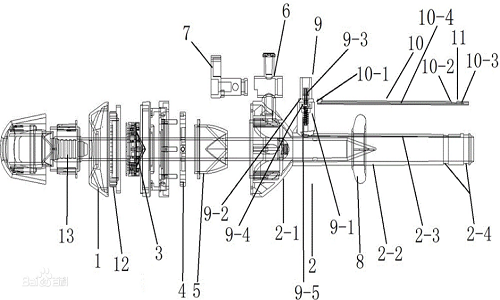

Implementation mode of laparoscopic trocar

Referring to figure 1-9, "laparoscopic trocar" includes locking cap 1, puncture sleeve assembly 2, locking cap assembly 3, locking switch 4, gas blocking cap 5, gas injection valve 6, gas injection switch 7, locating ring 8, check valve 9, sealing patch 10 and air bag 11. The puncture sleeve assembly 2 is composed of a puncture sleeve seat 2-1 and a puncture sleeve 2-2. The lower part of the puncture sleeve seat 2-1 is provided with a gas tight sealing cap installation groove 2-5, the upper part of the puncture sleeve seat 2-1 is provided with a locking sealing cap assembly installation groove 2-6, the gas tight sealing cap 5 is installed in the gas tight sealing cap installation groove 2-5 of the puncture sleeve, and the locking sealing cap assembly 3 is installed in the locking sealing cap assembly installation groove 2-6 on the upper part of the puncture sleeve seat. By locking the cap 1 Seal ring 12 is pressed and sealed.

The locking sealing cap assembly 3 has a casing elastic sealing cap 3-1, a casing sealing cap mounting seat 3-2, a locking fixed cap 3-3, and a lower gland 3-4. The casing elastic sealing cap 3-1 is installed on the casing sealing cap mounting base 3-2 and fixed by locking the fixed cap 3-3. The lower part of the casing sealing cap mounting base 3-2 is equipped with a lower gland 3-4. The casing elastic sealing cap 3-1 has elastic wrinkles, is conical, has elastic sealing effect, has elastic wrinkles, is conical, and can adjust the tightness to adapt to different surgical instruments. The casing elastic sealing cap 3-1 is inserted by locking the sealing components. The locking cap 1 and the sealing ring 12 can be fixed together by ultrasonic welding on the upper part of the puncture casing base. Two locking hooks 12-1 are arranged at the lower part of the sealing ring 12. The upper part of the puncture casing base 2-1 is provided with two locking hook installation jacks for inserting and fixing the locking hook 12-1. The upper part of the puncture casing base 2-1 is provided with a locking switch installation socket, and the locking switch 4 is inserted into the locking switch installation socket to lock and fix the locking cap 1, the sealing ring 12 and the locking cap assembly 3 on the puncture casing base 2-1.

The casing elastic sealing cap 3-1 has a plurality of conical silica gel sheets and silica gel pads, the conical silica gel sheets are sleeved on the silica gel pads and combined to form the casing elastic sealing cap 3-1. The casing elastic sealing cap 3-1 has elastic folds and is conical, and the bottom of the casing elastic sealing cap 3-1 is provided with a mounting hole. The casing sealing cap mounting base 3-2 is provided with a mounting column 3-2-1 and a mounting hole 3-2-2 for installing the casing elastic sealing cap 3-1. The locking fixed cover 3-3 is provided with an installation locking column 3-3-1 and an installation locking hole 3-3-2 for installing the elastic sealing cap 3-1 of the locking sleeve.

Post time: Jul-20-2022