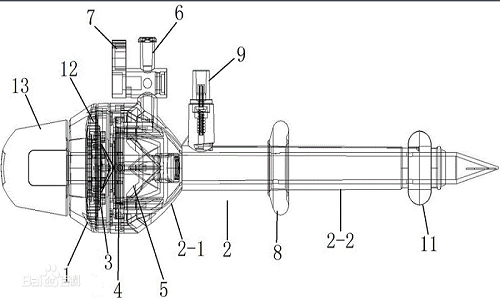

Technical scheme of laparoscopic trocar

The laparoscopic trocar includes a locking cap, a puncture sleeve assembly, a locking cap assembly, a locking switch, a gas blocking seal cap, a gas injection valve, a gas injection switch, a positioning ring, a one-way valve, a sealing patch and an air bag. The puncture casing assembly is composed of a puncture casing seat and a puncture casing. The lower part of the puncture casing seat is provided with a gas blocking sealing cap installation groove, the upper part of the puncture casing seat is provided with a locking sealing cap assembly installation groove, the gas blocking sealing cap is installed in the gas blocking sealing cap installation groove of the puncture casing, and the locking sealing cap assembly is installed in the locking sealing cap assembly installation groove on the upper part of the puncture casing seat The sealing ring is pressed and sealed.

The locking sealing cap assembly has a casing elastic sealing cap, a casing sealing cap mounting seat, a locking fixed cover, and a lower gland. The casing elastic sealing cap is installed on the casing sealing cap mounting base, which is locked and fixed by locking the fixed cover, and the lower part of the casing sealing cap mounting base is equipped with a lower gland. The sleeve elastic sealing cap has the function of elastic sealing, and can adjust the tightness to adapt to different surgical instruments. The sleeve elastic sealing cap that locks the sealing component is inserted. The locking cap and sealing ring can be fixed together by ultrasonic welding on the upper part of the puncture casing base. Two locking hooks are arranged at the lower part of the sealing ring. The upper part of the puncture casing base is provided with two locking hook installation jacks for locking hook installation and fixation. The upper part of the puncture casing base is provided with a locking switch installation socket, and the locking switch is inserted into the locking switch installation socket to lock and fix the locking cap, sealing ring and the locking cap assembly on the puncture casing base. The sleeve elastic sealing cap has a plurality of conical silica gel sheets and silica gel pads, the conical silica gel sheets are sleeved on the silica gel pads and pressed into a sleeve elastic sealing cap through combination. The sleeve elastic sealing cap has elastic folds and is conical, and the bottom of the sleeve elastic sealing cap is provided with a mounting hole.

The casing sealing cap mounting base is provided with a mounting column and a mounting hole for installing the casing elastic sealing cap. The locking fixed cover is provided with an installation locking column and an installation locking hole for installing the elastic sealing cap of the locking sleeve. The lower gland is provided with an installation pressing column and a support ring, which are used to support the shaped casing elastic sealing cap. The gas seal cap adopts a conical seal cap, which is made of elastic soft material and is gas seal. An air injection valve is installed on one side of the puncture casing seat, which is equipped with an air injection switch, an air inlet and an exhaust port. The air injection valve is connected with the air source through a pipe. During the operation, the air is injected into the cavity of the punctured surgical patient through the air injection valve to form an pneumoperitoneum, which is convenient for the operation. The outer side of the puncture sleeve is provided with a ventilation groove, which extends forward to the front of the puncture sleeve along the axial direction of the puncture tube and passes through the wire binding groove.

Two wire binding grooves are arranged around the front end of the puncture sleeve. A one-way valve is installed at the lower part of the puncture casing seat, and the air outlet of the one-way valve is connected with the ventilation groove outside the puncture tube. The sealing gland of the sealing patch is on the outside of the ventilation groove of the puncture sleeve, and an air transmission groove is arranged on the inside of the sealing patch, so that the ventilation groove forms a gas transmission channel. One end of the sealing patch is provided with a fixing block inserted and fixed at the bottom of the one-way valve, and the other end of the sealing patch is provided with a wiring groove and an air outlet corresponding to the front end of the puncture tube, which is convenient for wiring and fixing the airbag, and supplies air to the airbag through the air outlet. The sealing patch is pasted or the sealing gland is ultrasonically welded on the outside of the ventilation groove of the puncture sleeve, so that the ventilation groove forms a gas transmission channel. The air bag is installed at the front end of the puncture sleeve and fixed on the periphery of the binding groove by binding. The air outlet arranged by the sealing patch transmits compressed air to the air bag and inflates the air bag. The positioning ring is sleeved in the middle of the puncture sleeve. During the operation, when the puncture sleeve is inserted into the patient's cavity, the one-way valve inflates the air bag through the ventilation groove and the air outlet hole on the ventilation seal.

After the air bag is full of air, adjust the position of the positioning ring, clamp the puncture device on the patient's cavity tissue through the positioning ring and air bag sleeved on the puncture sleeve, and will not shake, which is convenient for surgical instruments to perform surgery. When the operation is completed, close the gas injection valve, open the gas injection switch, inflate the cavity, and then press the valve core of the one-way inflation valve to discharge the gas filled in the airbag, and then take out the puncture sleeve from the cavity wall of the patient. The one-way valve is a one-way gas injection valve. The one-way valve has a valve body, a valve seat, a valve core, a sealing ring and a spring. The sealing ring is installed on the valve core, and the spring presses the sealing ring of the valve core against the valve seat of the valve body to realize one-way sealing. The air inlet of the valve body is connected with the gas injection pipe and the compressed air source. The air bag is made of elastic soft film material. The locating ring is made of elastic soft material.

Post time: Jul-13-2022