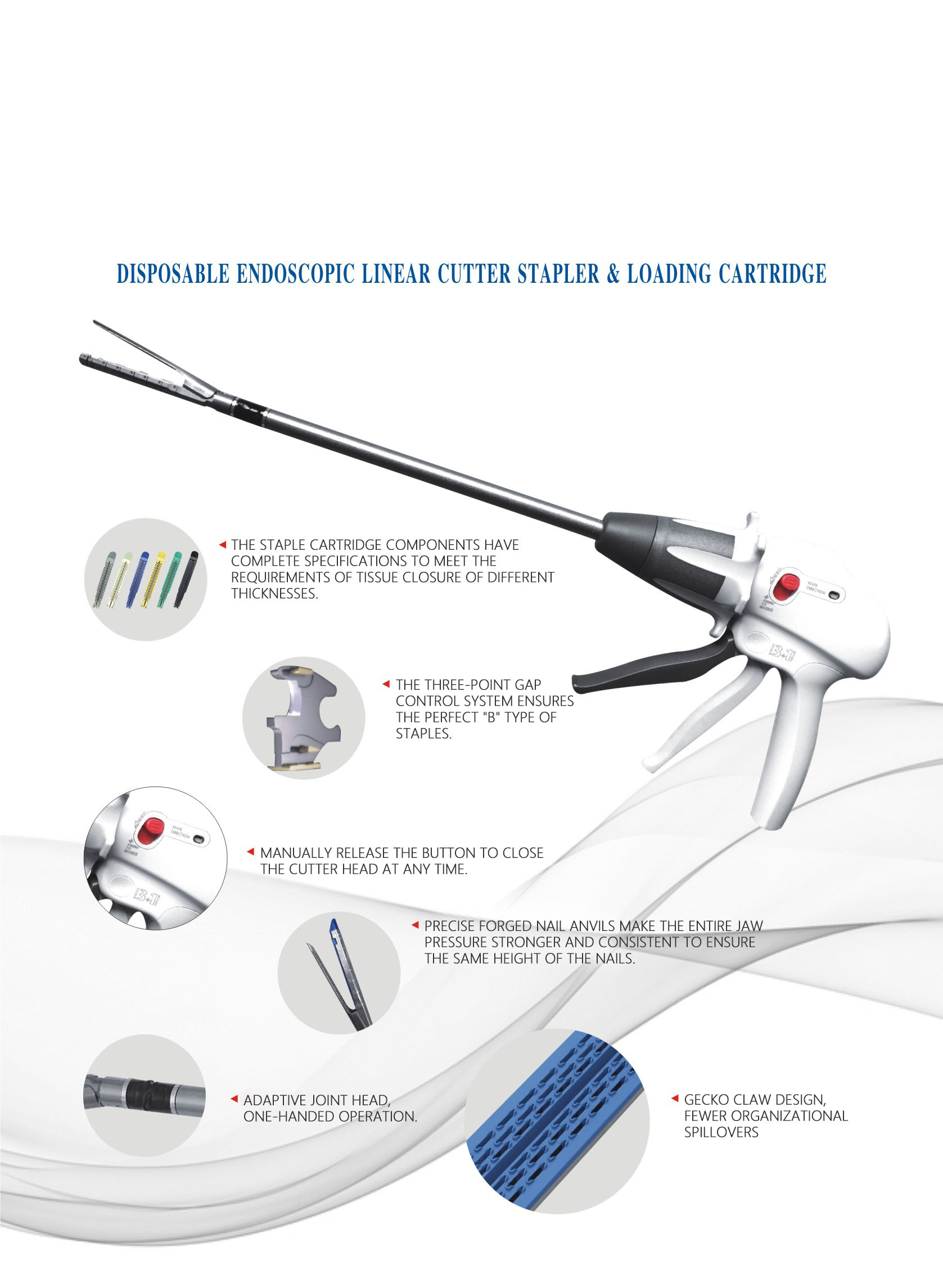

I-stapler entsha ye-Endoscopic|Laparoscopic stapler

- Alahlwayo endoscope linear cutting stapler kanye nezingxenye

- Ikhanda elihlangene eliguquguqukayo lingasebenza ngesandla esisodwa

- Khulula ngokuzenzela inkinobho ukuze uhoxise ikhanda lokusika noma kunini

- I-cartridge eyisisekelo inemininingwane ephelele yokuhlangabezana nezidingo zokuvalwa kwezicubu ze-diffe

- Isistimu yokulawula igebe lamaphuzu amathathu ukuze kuqinisekiswe ukubethelwa kohlobo B oluphelele

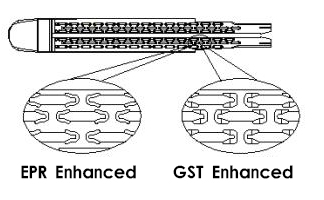

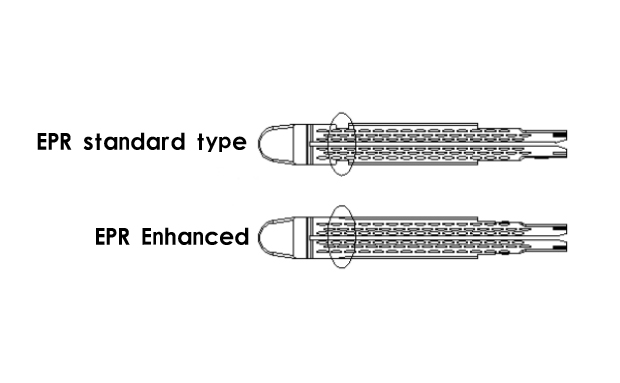

- Idizayini ye-staple cartridge emise uzipho lukaGecko idizayina ukuchichima kwezicubu ezimbalwa ukuze kuqinisekiswe i-anastomosis ephelele kakhulu

Isakhiwo kanye nokwakheka kwe-laparoscopic stapler:

I-Linear cutting stapler kanye nezingxenye ze-endoscope elahlwayo zakhiwa umzimba nokuhlanganiswa.

Umzimba uqukethe isihlalo sezinzipho, ikhanda elihlangene, induku, inkinobho ejikelezayo, i-paddle yokulungisa, inkinobho yokushintsha isiqondiso se-blade, iwindi lenkomba yokudubula, isiqondiso se-blade efasiteleni lenkomba, inkinobho yokukhulula, isibambo, isibambo esiseduze, isibambo sokudubula.

Yakhiwe ngommese wokusika kanye nesihlalo se-cartridge esiyisisekelo, futhi izingxenye zakhiwe nge-cartridge eyisisekelo nezipikili ze-anastomosis.Umkhiqizo unikezwa esimweni esiyinyumba futhi uhlanjululwe nge-ethylene oxide.

Ukusetshenziswa kanye.

Ububanzi besicelo se-laparoscopic stapler:

Ifanele ukuhlinzwa okuvulekile noma kwe-endoscopic, iqembu lamaphaphu kanye ne-bronchial, ukuluka nokukhishwa kabusha, i-transection kanye ne-anastomosis yesisu namathumbu.

I-Laparoscopic Linear Cutter Stapler elahlayo kanye nezingxenye

I. Igama lomkhiqizo, imodeli, imininingwane

Igama lomkhiqizo: I-endoscopic linear cutting stapler nezingxenye ezilahlwayo

Ukucaciswa kwemodeli:I-endoscopic linear cutting stapler elahlayo: PESS35, PESS45, PESS60, PESM35, PESM45, PESM60, PESL35, PESL45, PESL60, PEPS35, PEPS45, PEPS60, PEPM35, PEPM45, PEPM60, PEPL405, PEPL65, PEPL65, PEPL65;

Izingxenye ezilahlwayo ze-endoscopic ezisika imigqa yokusika: PSGST35M, PSGST35W, PSGST35B, PSGST35D, PSGST35G, PSGST35T, PSGST45M, PSGST45W, PSGST45B, PSGST45D, PSGST45W, PSGST35B, PSGST35D, PSGST35G, PSGST35T, PSGST45M, PSGST45W, PSGST45B, PSGST45D, PSGST45G, PSGST45G, PSGST45G, PSGST6SG, PSGST6SGST, PSGST4SG SGST35G, PSGST60T, PSGST60B, PSGST60T, PSGST60D, PSGST60B, PSGST35G , PSGST60D, PSGST60B PPEPR60D, PPEPR60G, PPEPR60T.

II.Ukusebenza komkhiqizo

I-stapler kufanele ibekwe ngendlela efanele, izingxenye ezishintshayo kufanele zibe lula, ziqine, futhi zingabi nazithiyo, futhi kufanele kube nemisindo noma okunye ukwaziswa lapho izingxenye zisendaweni.Izisekelo kufanele zilayishwe ngokuzinzile emhlanganweni, futhi okuyisisekelo akufanele zivezwe phezu kwe-cartridge eyisisekelo ngemva kokunyakaziswa.Ukuvulwa nokuvalwa kwemihlathi ye-stapler kufanele kube nezimo futhi akumele kube khona ukugxuma.Isakhiwo esihlangene kanye nesakhiwo sokujikeleza kwe-stapler kufanele kube nezimo futhi kungabi nazithiyo.Ukuxhumana phakathi komzimba we-stapler kanye nezingxenye kufanele kuqine futhi kuthembeke.Ngemva kokuba i-stapler inyakazisa ikhanda layo ku-engeli ephezulu, ingaqedela ngempumelelo ukudubula nokusetha kabusha.Kukhona amandla athile okubamba ngemva kokuvalwa kwemihlathi ye-stapler, futhi amandla okubamba akufanele abe ngaphansi kuka-4N.Kukhona amandla athile okuvala ngemva kokuba imihlathi ye-stapler ivaliwe, futhi amandla okuvala akufanele abe ngaphansi kuka-30N.Inokusebenza okuthile kwesandla esisodwa.I-stapler kufanele ibe nokusebenza kahle kwe-stapling kanye nokusika.Izingxenye ezishintshekayo zingasetshenziselwa ukusika nokunamathisela okuningi futhi hhayi izikhathi ezingaphansi kuka-8.Unqenqema lokusika ngemva kokunamathisela ngakunye kufanele lube luhle futhi lungabi nama-burrs, futhi ubude bendawo ekude yomugqa ngamunye wokugxilisa kufanele bube bude kunomugqa wokusika Ubude kufanele bube okungenani izikhathi ezingu-1.5 ubude bezinzipho, kanye nokuyisisekelo ngemva kwe-anastomosis ngayinye. kufanele kubunjwe njengo “B”.Umugqa oyisisekelo ngemva kwe-anastomosis kufanele ube namandla athile e-suture yomugqa oyisisekelo, futhi amandla e-suture yomugqa oyisisekelo akufanele abe ngaphansi kuka-0.1N/mm.I-stapler kufanele ibe nedivayisi yenkomba yempendulo yenqubo yokudubula engabonisa inqubo yokudubula noma isimo.

III.Isakhiwo esiyinhloko

I-endoscopic linear cutting stapler kanye nezingxenye ezilahlwayo zakhiwa umzimba kanye nezingxenye, lapho umzimba uqukethe i-anvil, ikhanda elihlangene, induku, i-rotary knob, i-paddle yokulungisa, inkinobho yokushintsha i-blade direction, iwindi lenkomba yokudubula, isiqondiso se-blade Sakhiwe iwindi lenkomba, inkinobho yokukhulula, isibambo, isibambo sokuvala, isibambo sokudubula, ummese wokusika, nesihlalo se-cartridge esiyisisekelo, umhlangano wakhiwe nge-cartridge eyisisekelo kanye nezinto eziyisisekelo.

IV.Ububanzi besicelo

Ilungele ukukhishwa kabusha, i-transection kanye ne-anastomosis yamaphaphu, izicubu ze-bronchial, isisu namathumbu ekuhlinzeni okuvulekile noma kwe-endoscopic.

Bheka Umfanekiso 1, Umfanekiso 2, Ithebula 1, kanye neThebula 2 ukuze uthole izinhlobo nobukhulu obuyisisekelo be-endoscopic linear cutting staplers kanye nezingxenye zokusika.

V. Ukubukeka nokwakheka komkhiqizo

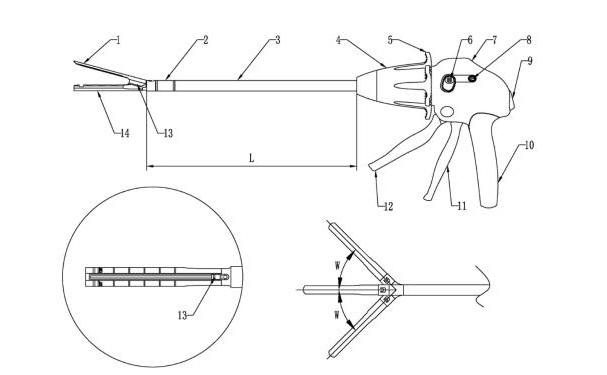

1—Isihlalo esivikela izinzipho, 2—Ikhanda elihlanganyelwe, 3—Induku;4—Inkinobho yokuzungezisa;5—I-paddle yokulungisa; 6—Inkinobho yokushintsha isiqondiso se-blade;7-Iwindi lesikhombi sokudubula;8-Iwindi lesikhombi se-blade;9—Inkinobho yokukhipha ;10—isibambo;11—isibambo sokuvala;12—isibambo sokudubula;13—ukusika ummese;Isihlalo se-cartridge engu-14

Umfanekiso 1 Umzimba we-linear cutting stapler ye-endoscopy elahlwayo

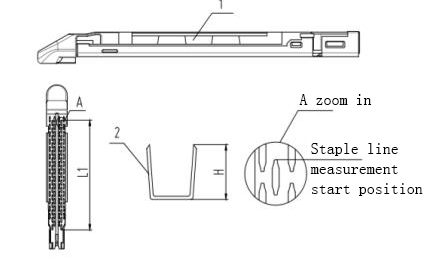

I-1-Staple bin 2-isisekelo

Umfanekiso 2 Umhlangano we-stapler wokusika olayini we-endoscope elahlwayo

Ithebula 1 Izilinganiso eziyisisekelo zomzimba

| Imininingwane Yemodeli | L(mm) | Ukubekezela (mm) | I-engeli egoqayo W (°) | Ukubekezelela (°) |

| I-PESS35 | 190 | ±5 | 45 | ±10 |

| I-PESM35 | 250 | |||

| I-PESL35 | 350 | |||

| I-PESS45 | 190 | |||

| I-PESM45 | 250 | |||

| I-PESL45 | 350 | |||

| I-PESS60 | 190 | |||

| I-PESM60 | 250 | |||

| I-PESL60 | 350 | |||

| I-PEPS35 | 190 | |||

| I-PEPM35 | 250 | |||

| I-PEPL35 | 350 | |||

| I-PEPS45 | 190 | |||

| I-PEPM45 | 250 | |||

| I-PEPL45 | 350 | |||

| I-PEPS60 | 190 | |||

| I-PEPM60 | 250 | |||

| I-PEPL60 | 350 |

Ithebula 1 Izilinganiso eziyisisekelo zomzimba

Qaphela: Izakhi ezinobude obufanayo obungu-35 zingasetshenziselwa kuphela umzimba onobude obufanayo obungu-35, izakhi ezinobude obufanayo obungu-45 zingasetshenziselwa kuphela umzimba onobude obufanayo obungu-45, kanye nezingxenye ezine ubude obuhambisanayo obungama-60 bungasetshenziswa kuphela ubude obuhambisanayo Umzimba ungama-60.

Ithebula 2 Iyunithi yobukhulu obuyisisekelo yezingxenye: mm

| imodeli | umbala | Ubude bomugqa oyisisekelo womugqa owodwa omude kakhulu wenhlangano (L1) | Toler ukhokho (mm) | Ubude boqobo besisekelo (H) | Ukubekezela (mm) | imodeli | umbala | Ubude bomugqa oyisisekelo womugqa owodwa omude kakhulu wenhlangano (L1) | Toler ukhokho (mm) | Ubude boqobo besisekelo (H) | Ukubekezela (mm) | |

| I-PSGST35M | Umlotha | 35.2 | ±2 | 2 | ±0.2 | I-PSEPR35M | Umlotha | 35.2 | ±2 | 2 | ±0.2 | |

| I-PSGST35W | Emhlophe | 35.2 | 2.6 | I-PSEPR35W | Emhlophe | 35.2 | 2.6 | |||||

| I-PSGST35B | eluhlaza okwesibhakabhaka | 35.2 | 3.6 | ±0.15 | I-PSEPR35B | eluhlaza okwesibhakabhaka | 35.2 | 3.6 | ±0.15 | |||

| I-PSGST35D | igolide | 35.2 | 3.8 | I-PSEPR35D | igolide | 35.2 | 3.8 | |||||

| I-PSGST35G | eluhlaza | 35.2 | 4.1 | ±0.1 | I-PSEPR35G | eluhlaza | 35.2 | 4.1 | ±0.1 | |||

| I-PSGST35T | mnyama | 35.2 | 4.2 | I-PSEPR35T | mnyama | 35.2 | 4.2 | |||||

| I-PSGST45M | Umlotha | 47.2 | 2 | ±0.2 | I-PSEPR45M | Umlotha | 47.2 | 2 | ±0.2 | |||

| I-PSGST45W | Emhlophe | 47.2 | 2.6 | I-PSEPR45W | Emhlophe | 47.2 | 2.6 | |||||

| I-PSGST45B | eluhlaza okwesibhakabhaka | 47.2 | 3.6 | ±0.15 | I-PSEPR45B | eluhlaza okwesibhakabhaka | 47.2 | 3.6 | ±0.15 | |||

| I-PSGST45D | igolide | 47.2 | 3.8 | I-PSEPR45D | igolide | 47.2 | 3.8 | |||||

| I-PSGST45G | eluhlaza | 47.2 | 4.1 | ±0.1 | I-PSEPR45G | eluhlaza | 47.2 | 4.1 | ±0.1 | |||

| I-PSGST45T | mnyama | 47.2 | 4.2 | I-PSEPR45T | mnyama | 47.2 | 4.2 | |||||

| I-PSGST60M | Umlotha | 59.3 | 2 | ±0.2 | PSEPR60M | Umlotha | 59.3 | 2 | ±0.2 | |||

| I-PSGST60W | Emhlophe | 59.3 | 2.6 | I-PSEPR60W | Emhlophe | 59.3 | 2.6 | |||||

| I-PSGST60B | eluhlaza okwesibhakabhaka | 59.3 | 3.6 | ±0.15 | I-PSEPR60B | eluhlaza okwesibhakabhaka | 59.3 | 3.6 | ±0.15 | |||

| I-PSGST60D | igolide | 59.3 | 3.8 | I-PSEPR60D | igolide | 59.3 | 3.8 | |||||

| I-PSGST60G | eluhlaza | 59.3 | 4.1 | ±0.1 | I-PSEPR60G | eluhlaza | 59.3 | 4.1 | ±0.1 | |||

| I-PSGST60T | mnyama | 59.3 | 4.2 | I-PSEPR60T | mnyama | 59.3 | 4.2 | |||||

| I-PPGST35M | Umlotha | 35.2 | 2 | ±0.2 | I-PPEPR35M | Umlotha | 35.2 | 2 | ±0.2 | |||

| I-PPGST35W | Emhlophe | 35.2 | 2.6 | I-PPEPR35W | Emhlophe | 35.2 | 2.6 | |||||

| I-PPGST35B | eluhlaza okwesibhakabhaka | 35.2 | 3.6 | ±0.15 | I-PPEPR35B | eluhlaza okwesibhakabhaka | 35.2 | 3.6 | ±0.15 | |||

| I-PPGST35D | igolide | 35.2 | 3.8 | I-PPEPR35D | igolide | 35.2 | 3.8 | |||||

| I-PPGST35G | eluhlaza | 35.2 | 4.1 | ±0.1 | I-PPEPR35G | eluhlaza | 35.2 | 4.1 | ±0.1 | |||

| I-PPGST35T | mnyama | 35.2 | 4.2 | I-PPEPR35T | mnyama | 35.2 | 4.2 | |||||

| I-PPGST45M | Umlotha | 47.2 | 2 | ±0.2 | I-PPEPR45M | Umlotha | 47.2 | 2 | ±0.2 | |||

| I-PPGST45W | Emhlophe | 47.2 | 2.6 | I-PPEPR45W | Emhlophe | 47.2 | 2.6 | |||||

| I-PPGST45B | eluhlaza okwesibhakabhaka | 47.2 | 3.6 | ±0.15 | I-PPEPR45B | eluhlaza okwesibhakabhaka | 47.2 | 3.6 | ±0.15 | |||

| I-PPGST45D | igolide | 47.2 | 3.8 | I-PPEPR45D | igolide | 47.2 | 3.8 | |||||

| I-PPGST45G | eluhlaza | 47.2 | 4.1 | ±0.1 | I-PPEPR45G | eluhlaza | 47.2 | 4.1 | ±0.1 | |||

| I-PPGST45T | mnyama | 47.2 | 4.2 | I-PPEPR45T | mnyama | 47.2 | 4.2 | |||||

| I-PPGST60M | Umlotha | 59.3 | 2 | ±0.2 | I-PPEPR60M | Umlotha | 59.3 | 2 | ±0.2 | |||

| I-PPGST60W | Emhlophe | 59.3 | 2.6 | I-PPEPR60W | Emhlophe | 59.3 | 2.6 | |||||

| I-PPGST60B | eluhlaza okwesibhakabhaka | 59.3 | 3.6 | ±0.15 | I-PPEPR60B | eluhlaza okwesibhakabhaka | 59.3 | 3.6 | ±0.15 | |||

| I-PPGST60D | igolide | 59.3 | 3.8 | I-PPEPR60D | igolide | 59.3 | 3.8 | |||||

| I-PPGST60G | eluhlaza | 59.3 | 4.1 | ±0.1 | I-PPEPR60G | eluhlaza | 59.3 | 4.1 | ±0.1 | |||

| I-PPGST60T | mnyama | 59.3 | 4.2 | I-PPEPR60T | mnyama | 59.3 | 4.2 |

VI.Contraindications

1).i-edema ye-mucosa enzima;

2).Kwenqatshelwe ngokuphelele ukusebenzisa le divayisi esibindini noma esicutshini sobende.Ngenxa yezakhiwo ezicindezelayo zezicubu ezinjalo, ukuvalwa kwedivayisi kungase kube nomphumela olimazayo;

3).Ayikwazi ukusetshenziswa ezingxenyeni lapho i-hemostasis ingabonakali khona;

4).Izingxenye ezimpunga azikwazi ukusetshenziselwa izicubu ezinogqinsi olungaphansi kuka-0.75mm ngemva kokucindezelwa noma izicubu ezingakwazi ukucindezelwa kahle zibe ukujiya okungu-1.0mm;

5).Izingxenye ezimhlophe azikwazi ukusetshenziselwa izicubu ezinogqinsi olungaphansi kuka-0.8mm ngemva kokucindezelwa noma izicubu ezingakwazi ukucindezelwa kahle zibe ukujiya okungu-1.2mm;

6).Ingxenye eluhlaza okwesibhakabhaka akufanele isetshenziselwe izicubu ezinogqinsi olungaphansi kuka-1.3mm ngemva kokucindezelwa noma ezingakwazi ukucindezelwa kahle zibe ukujiya okungu-1.7mm.

7).Izingxenye zegolide azikwazi ukusetshenziselwa izicubu ezinogqinsi olungaphansi kuka-1.6mm ngemva kokucindezelwa noma izicubu ezingakwazi ukucindezelwa kahle zibe ukujiya okungu-2.0mm;

8).Ingxenye eluhlaza okotshani akufanele isetshenziselwe izicubu ezinogqinsi olungaphansi kuka-1.8mm ngemva kokucindezelwa noma ezingakwazi ukucindezelwa kahle zibe ukujiya okungu-2.2mm.

9).Ingxenye emnyama akufanele isetshenziselwe izicubu ezingaphansi kuka-2.0mm ubukhulu ngemva kokucindezelwa noma ezingakwazi ukucindezelwa kahle zibe ukujiya okungu-2.4mm.

10).Kwenqatshelwe ngokuphelele ukusebenzisa izicubu ku-aorta.

VII.Isetshenziswa kanjani

Imiyalo yokufaka i-cartridge eyisisekelo:

1).Khipha ithuluzi kanye nekhatriji eliyisisekelo kumaphakheji abo ahlukene ngaphansi kokusebenza kwe-aseptic;

2).Ngaphambi kokulayisha i-cartridge yesisekelo, qiniseka ukuthi insimbi isesimweni esivulekile;

3).Hlola ukuthi i-cartridge eyisisekelo inaso yini isembozo sokuzivikela.Uma i-cartridge eyisisekelo ingenayo isembozo sokuzivikela, akuvunyelwe ukuyisebenzisa;

4).Namathisela i-cartridge yesisekelo phansi kwesihlalo se-cartridge esiyisisekelo somhlathi, usifake ngendlela eshelelayo kuze kube yilapho i-cartridge yesisekelo ihambisana ne-bayonet, lungisa i-cartridge eyisisekelo bese ususa isembozo sokuzivikela.Ngalesi sikhathi, insimbi isilungele ukuvutha;(Qaphela: Ngaphambi kokuthi kufakwe i-staple cartridge endaweni, sicela ungasikhiphi ikhava yokuvikela i-staple cartridge.)

5).Lapho ukhipha i-cartridge yesisekelo, phusha i-staple cartridge ibheke ngasesihlalweni sezipikili ukuze uyikhulule esihlalweni se-cartridge esiyisisekelo;

6).Ukuze ufake i-cartridge entsha eyisisekelo, phinda izinyathelo 1-4 ngenhla.

Imiyalo yokuhlinzwa:

1).Vala isibambo sokuvala, futhi umsindo othi "chofoza" ubonisa ukuthi isibambo sokuvala sikhiyiwe, futhi i-occlusal surface ye-cartridge eyisisekelo isesimweni esivaliwe;Qaphela: Ungasibambi isibambo sokudubula ngalesi sikhathi

2).Uma ungena emgodini womzimba nge-cannula noma i-incision ye-trocar, i-occlusal surface yensimbi kufanele idlule ku-cannula ngaphambi kokuba i-occlusal surface ye-cartridge eyisisekelo ingavulwa;

3).Insimbi ingena emgodini womzimba, cindezela inkinobho yokukhulula, vula indawo efihlekile yensimbi, bese usetha kabusha isibambo sokuvala.

4).Vula inkinobho ejikelezayo ngomunwe wakho wenkomba ukuze ujikeleze, futhi ingalungiswa ngamadigri angu-360;

5).Khetha indawo efanelekile (efana nesakhiwo somzimba, isitho noma enye insimbi) njengendawo yokuxhumana, donsa i-paddle yokulungisa uyibuyisele emuva ngomunwe wokukhomba, sebenzisa amandla okusabela nendawo yokuxhumana ukuze ulungise i-engeli egobayo, futhi uqinisekise ukuthi i-cartridge eyisisekelo ingaphakathi kwenkundla yombono.

6).Lungisa ukuma kwensimbi kusicubu ukuze i-anastomosed/isikwe;

Qaphela: Qinisekisa ukuthi izicubu zibekwe endaweni eyisicaba phakathi kwezindawo ze-occlusal, azikho izithiyo endaweni ye-occlusal, njengeziqeshana, abakaki, izintambo zokuqondisa, njll., futhi ukuma kuyafaneleka.Gwema ukusikeka okungaphelele, okuyisisekelo okungakhiwe kahle, kanye/noma ukwehluleka ukuvula izindawo ezifihlekile zethuluzi.

7).Ngemva kokuba insimbi ikhethe izicubu ezizokwenziwa i-anastomosed, vala isibambo size sikhiye futhi uzwe/uzwe umsindo othi “chofoza”;

8).Idivayisi yokudubula.Sebenzisa imodi ethi “3+1″ ukuze wenze umsebenzi wokusika nokuthunga okuphelele;“3″: bamba isibambo sokudubula ngokugcwele ngokunyakaza okushelelayo, bese usikhulula size silingane nesibambo sokuvala.Ngasikhathi sinye, qaphela ukuthi inombolo esefasiteleni lenkomba yokudubula ithi "1" "Lesi yisifo sohlangothi, inani lizokhula ngo-"1" nge-stroke ngayinye, isamba semivimbo emi-3 elandelanayo, ngemuva kokushaywa kwesithathu, i-blade. amafasitela ezinkomba zokuqondisa kuzo zombili izinhlangothi zesibambo esilungisiwe esimhlophe azokhomba ekugcineni kwethuluzi, okubonisa ukuthi ummese ukumodi yokubuyisela, ubambe futhi ukhulule isibambo sokudubula futhi, iwindi lenkomba lizobonisa u-0, okubonisa ukuthi ummese ibuyele endaweni yayo yokuqala;

9).Cindezela inkinobho yokukhipha, vula indawo ye-occlusal, bese usetha kabusha isibambo sokudubula sesibambo sokuvala;

Qaphela: Cindezela inkinobho yokukhipha, uma i-occlusal surface ingavulwa, qala ngokuqinisekisa ukuthi iwindi lenkomba liyabonisa u-“0″ nokuthi iwindi lesikhombi se-blade likhomba ohlangothini oluseduze lwethuluzi ukuze uqinisekise ukuthi ummese usekuqaleni. isikhundla.Uma kungenjalo, udinga ukucindezela inkinobho yokushintsha isiqondiso se-blade ukuze uhlehlise isiqondiso se-blade, futhi ubambe ngokugcwele isibambo sokudubula size silingane nesibambo sokuvala, bese ucindezela inkinobho yokukhulula;

10).Ngemva kokukhulula izicubu, hlola umphumela we-anastomosis;

11).Vala isibambo sokuvala bese ukhipha insimbi.

VIII.Ukugcinwa nokugcinwa komkhiqizo izindlela

1. Isitoreji: Gcina ekamelweni elinomswakama olinganiselwe ongekho ngaphezu kuka-80%, elinomoya ohlanzekile, futhi elingenawo amagesi ezonakalisayo.

2. Ezokuthutha: Umkhiqizo opakishiwe ungathuthwa ngamathuluzi avamile.Ngesikhathi sokuthutha, kufanele kuphathwe ngokucophelela futhi ugweme ilanga eliqondile, ukungqubuzana okunamandla, imvula kanye ne-gravity extrusion.

IV.Usuku lokuphelelwa isikhathi

Ngemuva kokuthi umkhiqizo usufakwe inzalo nge-ethylene oxide, isikhathi sokuvala inzalo iminyaka emithathu, futhi usuku lokuphelelwa yisikhathi luboniswa kulebula.

X. Uhlu lwezingxenye

akukho

XI, Izinyathelo Zokuqaphela, Izexwayiso

1. Uma usebenzisa lo mkhiqizo, imininingwane yokusebenza kwe-aseptic kufanele ilandelwe ngokuqinile;

2. Sicela uhlole ukupakishwa kwalo mkhiqizo ngokucophelela ngaphambi kokusetshenziswa, uma ukupakishwa kwamabhamuza konakalisiwe, sicela uyeke ukuyisebenzisa;

3. Lo mkhiqizo uvalwa inzalo nge-ethylene oxide, futhi umkhiqizo ovalwe inzalo owokusetshenziswa emtholampilo.Sicela uhlole inkomba yediski ebhokisini lokupakisha lokuvala inzalo lalo mkhiqizo, “okuluhlaza okwesibhakabhaka” kusho ukuthi umkhiqizo uvalwe amagciwane futhi ungasetshenziswa ngokuqondile emtholampilo;

4. Lo mkhiqizo usetshenziselwa ukuhlinzwa okukodwa futhi awukwazi ukuvalwa inzalo ngemva kokusetshenziswa;

5. Sicela uhlole ukuthi umkhiqizo ungaphakathi kwesikhathi sokuqinisekisa ngaphambi kokusetshenziswa.Isikhathi sokuqinisekisa ukuvala inzalo iminyaka emithathu.Imikhiqizo engaphezulu kwesikhathi sokuqinisekisa inqatshelwe ngokuphelele;

6. Umhlangano wokusika i-laparoscopic okhiqizwe yinkampani yethu kufanele usetshenziswe ngokuhambisana nohlobo oluhambisanayo kanye nokucaciswa kwe-laparoscopic linear cutting stapler ekhiqizwa yinkampani yethu.Bheka iThebula 1 kanye neThebula 2 ukuze uthole imininingwane;

7. Imisebenzi ehlasela kancane kufanele yenziwe abantu abathole ukuqeqeshwa okwanele futhi abajwayelene namasu amancane ahlaselayo.Ngaphambi kokwenza noma yikuphi ukuhlinza okuncane kakhulu, izincwadi zezokwelapha ezihlobene nenqubo, izinkinga zayo kanye nezingozi kufanele kuboniswane nazo;

8. Usayizi wemishini ehlasela kancane evela kubakhiqizi abahlukene ungahluka.Uma amathuluzi okuhlinza ahlasela kancane kanye nezinsiza zawo ezikhiqizwe abakhiqizi abahlukene kusetshenziswa ekuhlinzeni okukodwa ngesikhathi esisodwa, kuyadingeka ukuthi kubhekwe ukuthi ayahambisana yini ngaphambi kokuhlinzwa;

9. Ukwelashwa ngemisebe ngaphambi kokuhlinzwa kungase kubangele ukushintsha kwezicubu.Isibonelo, lezi zinguquko zingabangela ukuqina kwezicubu ngaphezu kwalokho okushiwo kusisekelo esikhethiwe.Noma yikuphi ukwelashwa kwesiguli ngaphambi kokuhlinzwa kufanele kucatshangelwe ngokucophelela futhi kungadinga izinguquko endleleni yokuhlinza noma indlela;

10. Ungaliyeki inkinobho kuze kube yilapho insimbi isilungele ukuvutha;

11. Qiniseka ukuthi ubheka ukuphepha kwekhatriji eliyisisekelo ngaphambi kokudubula;

12. Ngemuva kokudubula, qiniseka ukuthi uhlola i-hemostasis emgqeni we-anastomotic, hlola ukuthi i-anastomosis iphelele nokuthi kukhona ukuvuza;

13. Qinisekisa ukuthi ukujiya kwezicubu kungaphakathi kwebanga elishiwo nokuthi izicubu zisabalaliswa ngokulinganayo ngaphakathi kwe-stapler.Izicubu eziningi kakhulu ohlangothini olulodwa zingabangela i-anastomosis embi, futhi ukuvuza kwe-anastomotic kungase kwenzeke;

14. Endabeni yezicubu ezingaphezu noma eziwugqinsi, ukuzama ukuphoqelela i-trigger kungase kubangele ama-sutures angaphelele kanye nokuphuka kwe-anastomotic noma ukuvuza okungenzeka.Ngaphezu kwalokho, ukulimala kwensimbi noma ukwehluleka ukushisa kungase kwenzeke;

15. Kumele kuqedwe ukudubula okukodwa.Ungalokothi ushise insimbi kancane.Ukudubula okungaphelele kungase kubangele izisekelo ezakhiwe ngendlela engafanele, umugqa wokusika ongaphelele, ukopha nokuvuza kumthungo, kanye/noma kube nzima ukukhipha ithuluzi;

16. Qinisekisa ukuthi ushisa kuze kube sekugcineni ukuze uqinisekise ukuthi izisekelo zakhiwe ngendlela efanele futhi izicubu zisikwa ngendlela efanele;

17. Cindezela isibambo sokudubula ukuze uveze i-blade yokusika.Ungacindezeli isibambo ngokuphindaphindiwe, okuzodala umonakalo endaweni ye-anastomosis;

18. Lapho ufaka idivayisi, qinisekisa ukuthi ukuphepha kusendaweni evaliwe ukuze ugweme ukwenza kusebenze ngokungazi kwe-lever yokudubula, okuholela ekuvezweni kwe-blade ngengozi kanye nokusetshenziswa okuyingxenye ngaphambi kwesikhathi noma okugcwele kwezisekelo;

19. Izikhathi eziphezulu zokudubula zalo mkhiqizo izikhathi ezingu-8;

20. Ukusebenzisa lolu cingo ngezinto zokuqinisa ulayini we-anastomotic kungase kunciphise inani lamashothi;

21. Lo mkhiqizo uyidivayisi esetshenziswa kanye.Uma idivayisi isivuliwe, kungakhathaliseki ukuthi isetshenzisiwe noma cha, ngeke iphinde inzalwe.Qiniseka ukuthi ukhiya ilokhi yokuphepha ngaphambi kokuphatha;

22. Iphephile ngaphansi kwezimo ezithile ze-nuclear magnetic resonance (MR):

·Ukuhlola okungekhona okomtholampilo kubonisa ukuthi okuyisisekelo okugxilile okunebanga le-TA2G lezinto ezibonakalayo kungasetshenziswa ku-MR ngokwemibandela.Iziguli zingaskenwa ngokuphephile ngokushesha ngemva kokufakwa okuyisisekelo kulezi zimo ezilandelayo:

·Ibanga lenkundla kazibuthe emile liphakathi kuka-1.5T-3.0T kuphela.

·Ubukhulu bendawo kazibuthe begradient bungu-3000 gauss/cm noma ngaphansi.

·Isistimu ye-MR enkulu kunazo zonke ebikiwe, iskena imizuzu engu-15, isilinganiso sokumunca okumaphakathi komzimba wonke (SAR) singu-2 W/kg.

·Ngaphansi kwezimo zokuskena, ukukhuphuka kwezinga lokushisa okuphezulu kwama-staples kulindeleke ukuthi kube ngu-1.9°C ngemva kokuskena imizuzu engu-15.

Ulwazi lwe-artifact:

Lapho kuhlolwa ngokungekho emthethweni kusetshenziswa isithombe sokulandelana kwe-gradient echo pulse kanye nohlelo lukazibuthe olumile lwe-3.0T MR, okuyisisekelo kubangele ama-artifacts acishe abe ngu-5 mm ukusuka endaweni yokufakelwa.

23. Bheka ilebula ngosuku lokukhiqiza;